Product Information

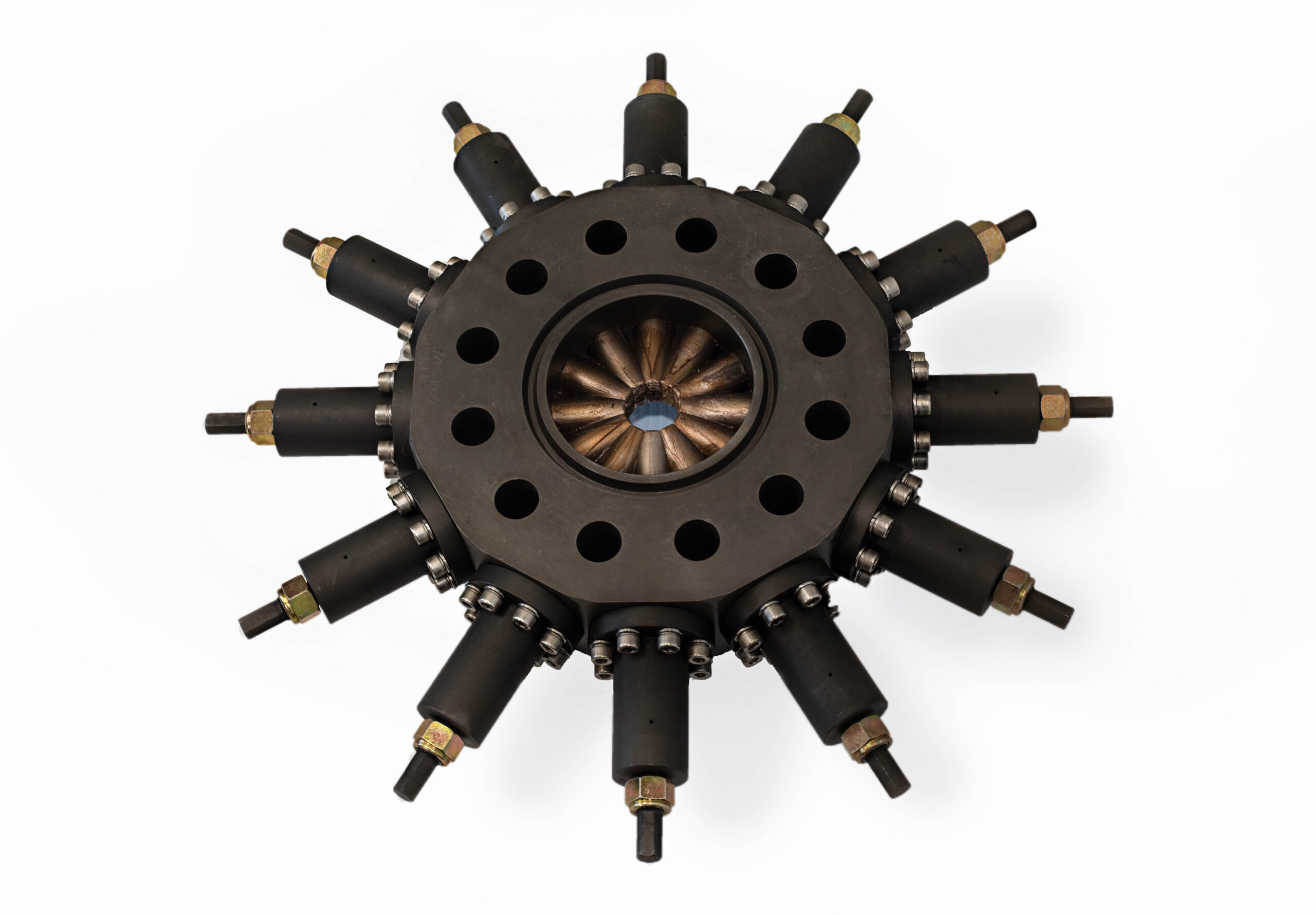

Mitey Titan Hanger Flanges serve as vital safety apparatus during well servicing and under balance drilling operations, allowing for the secure hanging off of tubing strings. These flanges are designed with manually extendable and retractable rams, capable of engaging a range of tubular sizes while ensuring full bore when the rams are fully retracted. The Hanger Flange Ram ends are engineered similarly to the MT Gripper Slip Dies, providing vertical support to hold the tubular string in place using the Hanger Flange.

Request a

quote

"*" indicates required fields